To any one familiar with the history of the technique of relief engraving, the reading of Mr. Tokuno's communication makes it evident that the methods used by the Japanese engravers of today, so far as they have not been influenced by European precept, are precisely those used in Europe in the 15th, 16th and 17th centuries. In other words, these artists are not, correctly speaking, wood-engravers, but wood-cutters. This is apparent from the material and the tools used by them.

The material is wood cut in the direction of the fiber, i. e., planks, for which, since Bewick's time, blocks cut across the fiber or grain have been substituted with us.

The

tools are knives, which with us have been displaced by gravers. It is interesting to

compare the representation of a Japanese wood cutter (Pl. VI) with

the oldest known representation of a European wood-cutter (Fig. 2),

here reproduced from Jost Amman's "Beschreibung aller Stande"

(generally, although not quite correctly, called "Book of Trades"),

published in Frankfort-on-the-Main in the year 1568. As Jost Amman

was a very prolific designer for wood cutters, be must have been

thoroughly familiar with the craft, and his representation may

therefore be accepted as reliable. At first sight the way of holding

the tool adopted by Amman's "Formschneider" (form-cutter,

i. e., wood

cutter) impresses one as peculiar, and perhaps unwarranted. A glance

at Pl. VI, however, shows a striking analogy between the manner of

holding the tool of the Japanese "Formschneider" of today and that of

his European predecessor of the sixteenth century, i. e., they both hold the tool

perpendicularly, the only difference being that the Asiatic uses also

the left hand in guiding it. The modern Japanese document may

therefore serve to confirm the correctness of Jost Amman's

delineation.

The

tools are knives, which with us have been displaced by gravers. It is interesting to

compare the representation of a Japanese wood cutter (Pl. VI) with

the oldest known representation of a European wood-cutter (Fig. 2),

here reproduced from Jost Amman's "Beschreibung aller Stande"

(generally, although not quite correctly, called "Book of Trades"),

published in Frankfort-on-the-Main in the year 1568. As Jost Amman

was a very prolific designer for wood cutters, be must have been

thoroughly familiar with the craft, and his representation may

therefore be accepted as reliable. At first sight the way of holding

the tool adopted by Amman's "Formschneider" (form-cutter,

i. e., wood

cutter) impresses one as peculiar, and perhaps unwarranted. A glance

at Pl. VI, however, shows a striking analogy between the manner of

holding the tool of the Japanese "Formschneider" of today and that of

his European predecessor of the sixteenth century, i. e., they both hold the tool

perpendicularly, the only difference being that the Asiatic uses also

the left hand in guiding it. The modern Japanese document may

therefore serve to confirm the correctness of Jost Amman's

delineation.

Of the shape of the knife used by the old wood-cutters of Europe and of the way of grinding it, we have no positive knowledge, as the representations of tools which often accompany the monograms of the "Formschneider" on sixteenth century wood-cuts are too small, and oftentimes too fantastic, to be of any use for information. The knives or "engraving points," as he called them, used by J. M. Papillon, the well-known French wood-cutter of the eighteenth century, are figured and fully described in his "Traite de la Gravure en Bois," 2 volumes, Paris, 1766. The blades were made of clock springs mounted in split wooden handles, in which they were fastened by means of a piece of string wound around them.

Fig. 3

shows one of these knives, actual size, reproduced from Pl.

IV in Papillon's

second volume. It is flat on the side not shown in the illustration,

beveled on the side shown, and cut off obliquely at the extremity.

The straight edge is the cutting edge. The Japanese knife (see Fig.

1) at first sight seems to be similarly constructed. Its blade is,

indeed, heavier, but it is mounted in a somewhat similar handle, not

split, however, but with only a slit in it, into which the blade is

wedged, and in which it is held in place by a ferrule. [*6] It is furthermore

beveled on one side like Papillon's knife; but the bevel is on the

opposite side, and there is a bevel also along the edge which forms

an angle with the long edge of the knife. This is necessary, because

the cutting edge is the short oblique one and not the long edge. That

this is so is apparent from the way in which the Japanese wood-cutter

holds the knife on Pl. VI.

Fig. 3

shows one of these knives, actual size, reproduced from Pl.

IV in Papillon's

second volume. It is flat on the side not shown in the illustration,

beveled on the side shown, and cut off obliquely at the extremity.

The straight edge is the cutting edge. The Japanese knife (see Fig.

1) at first sight seems to be similarly constructed. Its blade is,

indeed, heavier, but it is mounted in a somewhat similar handle, not

split, however, but with only a slit in it, into which the blade is

wedged, and in which it is held in place by a ferrule. [*6] It is furthermore

beveled on one side like Papillon's knife; but the bevel is on the

opposite side, and there is a bevel also along the edge which forms

an angle with the long edge of the knife. This is necessary, because

the cutting edge is the short oblique one and not the long edge. That

this is so is apparent from the way in which the Japanese wood-cutter

holds the knife on Pl. VI.

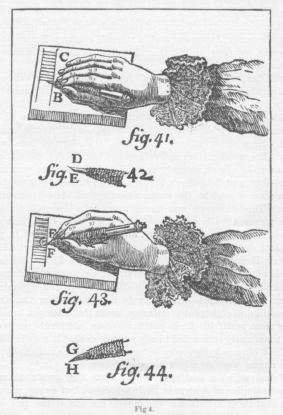

It is worth remarking that Papillon's way of holding the knife differed radically from that of his European predecessors and of the Japanese wood-cutters of to-day. Fig. 4, also taken from Papillon's second volume, illustrates this point.

In the

method of transferring the design to the plank, we again find a close

analogy; for although the early wood-cut draftsmen of Europe in most

cases, probably, drew their designs directly on the wood with pen and

ink, it is well known also that some times the drawing was made on a

sheet of paper and pasted on the plank, face downward, in precisely

the way which is practiced in Japan at present.

In the

method of transferring the design to the plank, we again find a close

analogy; for although the early wood-cut draftsmen of Europe in most

cases, probably, drew their designs directly on the wood with pen and

ink, it is well known also that some times the drawing was made on a

sheet of paper and pasted on the plank, face downward, in precisely

the way which is practiced in Japan at present.

Still more curious, however, is the similarity between the instrument, "baren," used by the printers of Japan, and the earliest contrivance for taking impressions from cut blocks, of which mention is made, so far as at present known, in a European book. The "baren" has the form of a little shield. In the treatise on painting, written by Cennino Cennini da Colle di Valdelse, towards the close of the fourteenth century, chapter 173, entitled "How to paint on cloth with a form," the following directions are given: A wood block upon which the design has been cut is to be charged with color. For this purpose a glove is to be worn on the left hand, the color to be used is to be spread on the palm of the hand, and the block is then to be charged with the color, "carefully, so that the parts cut out do not fill up," the gloved hand doing the office of a printer's ball. The cloth is now to be laid on the block charged with color, and then, continues Cennini, "take a shield of wood in the right and press with the back upon the surface, so far as the cut plank will bear it." It is, however, apparent from this most summary description that Cennini's rude contrivance is not to be compared for efficiency with the Japanese "baren," with its twisted cord packing and ribbed bamboo sheath. Nor does the printing shield mentioned by Cennini seem to have come largely into use, for the instruments generally supposed to have been employed in Europe for taking impressions previous to the introduction of the press are rubbers (which, however, might have been shield-shaped) and rollers, of which the latter remained in use for the taking of proofs down to the time of Papillon, who describes and figures them in the book before cited.

That the method of plugging practiced by the Japanese wood-cutters - evidently by square instead of round plugs - is the same as the old European method is not to be wondered at in view of the identity of the materials used.