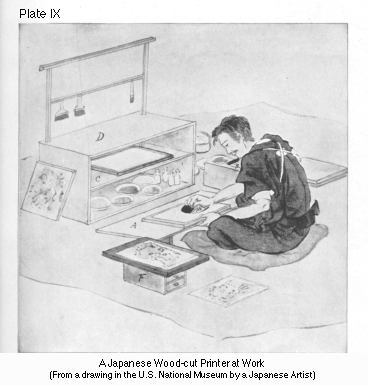

THE PRINTER AND PRINTING. The method of taking impressions is illustrated on Plate

IX.  The

printer seats himself, and arranges all the tools and materials

required, in good order, as shown. The plank to be printed is placed

on the printer's table A, and the required color is laid on with the brush

B. The paper

being ready for printing, and having been placed upon the shelf

C of the box

D, a sheet of it

is laid down upon the plank, and is rubbed lightly with the "baren"

E. The printed

sheet is then placed on a board which rests upon the box

F, used for

keeping colors, color dishes, etc., and when the required number of

sheets has been printed, they are put back on the shelf

C. Another plank

is now taken, the second impression is made upon the sheets bearing

the first, and this is followed by the third, fourth, etc., until the

printing is completed.

The

printer seats himself, and arranges all the tools and materials

required, in good order, as shown. The plank to be printed is placed

on the printer's table A, and the required color is laid on with the brush

B. The paper

being ready for printing, and having been placed upon the shelf

C of the box

D, a sheet of it

is laid down upon the plank, and is rubbed lightly with the "baren"

E. The printed

sheet is then placed on a board which rests upon the box

F, used for

keeping colors, color dishes, etc., and when the required number of

sheets has been printed, they are put back on the shelf

C. Another plank

is now taken, the second impression is made upon the sheets bearing

the first, and this is followed by the third, fourth, etc., until the

printing is completed.

Charging the block with color. ["Inking" the block.] As before stated, the pigment to be used is put on the block or plank, and some rice paste is then sprinkled upon it. It is well, also, to soak the brush properly with this paste, so as to mix it thoroughly with the pigment. This increases the brilliancy of the colors, and also fixes them more completely. [Ed. note]

Dry impression. [Embossing.] There is a special kind of printing, called "dry impression." This is used when it is desired to represent designs of the same color as the ground, but differing in brilliancy. It is executed after the printing has been finished, and the paper has be come quite dry. The sheet is then laid upon a plank specially cut for the purpose, but not charged with color, and is rubbed with the "baren" [*4] [Ed. note]

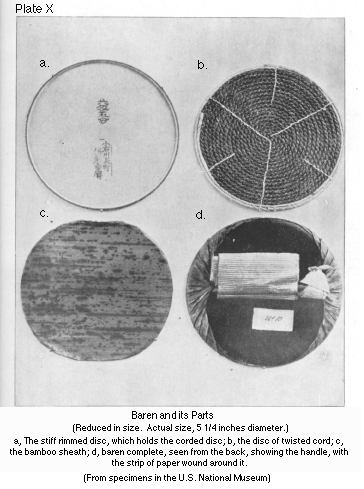

The "baren" and the method of using it. The "baren"(see Plate X a-d)

is a little hard shield, d, consisting of a stiff disk

a, made of

layers of paper pasted together, and turned up at the edge so as to

form a very shallow receptacle, and covered with cotton cloth on the

outside. A second disk b, formed of twisted cord, fits into this shallow receptacle,

and is held in. place by the bamboo sheath c, made of the ribbed leaf of

the bamboo, which is drawn tightly over it and twisted together on

the back, so as to form a handle. This latter is made more convenient

for the hand to grasp it by a strip of paper wound around it and so

arranged as to assume the shape of a rectangular pad. [*5] [Ed.

note] The reason why it is made so hard,

besides making the filling of twisted cord, is to prevent its bending

during use. Moreover, if it were not so hard and rigid, the full

stretching of the bamboo sheath would be impossible. The ribbed

surface of the bamboo serves not only to get a sharper impression, by

limiting the contact to the ribs, but it also prevents the adhesion

of the wet paper to the "baren," which would occur, to the spoiling

of the paper, if the covering were smooth. The contacting surface

should be applied only to those parts of the plank which have been

left standing in relief. If this precaution is neglected, there is

the possibility of smearing from the depressed parts of the block.

The direction in the movement of the "baren" should be zigzag, as

shown on Plate XI,

The "baren" and the method of using it. The "baren"(see Plate X a-d)

is a little hard shield, d, consisting of a stiff disk

a, made of

layers of paper pasted together, and turned up at the edge so as to

form a very shallow receptacle, and covered with cotton cloth on the

outside. A second disk b, formed of twisted cord, fits into this shallow receptacle,

and is held in. place by the bamboo sheath c, made of the ribbed leaf of

the bamboo, which is drawn tightly over it and twisted together on

the back, so as to form a handle. This latter is made more convenient

for the hand to grasp it by a strip of paper wound around it and so

arranged as to assume the shape of a rectangular pad. [*5] [Ed.

note] The reason why it is made so hard,

besides making the filling of twisted cord, is to prevent its bending

during use. Moreover, if it were not so hard and rigid, the full

stretching of the bamboo sheath would be impossible. The ribbed

surface of the bamboo serves not only to get a sharper impression, by

limiting the contact to the ribs, but it also prevents the adhesion

of the wet paper to the "baren," which would occur, to the spoiling

of the paper, if the covering were smooth. The contacting surface

should be applied only to those parts of the plank which have been

left standing in relief. If this precaution is neglected, there is

the possibility of smearing from the depressed parts of the block.

The direction in the movement of the "baren" should be zigzag, as

shown on Plate XI,

but if a very small and isolated part of the design is to be printed, it is better to give a lighter rub with the edge of the instrument.

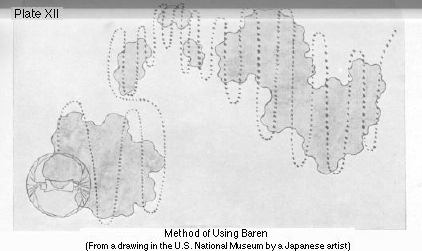

On Plate XII the dotted line shows the direction of the "baren," while the solid curved lines mark the outlines of the design. The rib of the bamboo sheath should be kept as nearly as possible at a right angle to the direction of the "baren."

Smearing from the depressions of the block. As the depressions of the cut planks - that is to say, those parts which have been cut away between the lines and masses of the design - are rather shallow, and at the same time in many cases quite extensive, it would seem almost impossible to prevent the sinking of the sheet into the depressions and taking the color in these places, more especially when the method of applying the printing color with a brush is considered, which makes it impossible to keep the depressions clean. Experienced printers, nevertheless, work without fear of smearing, and no special precautions are used to guard against it.

Registering. As each color requires a separate cut, each plank must have certain fixed marks [registering marks], so that all the sheets may be laid down in exactly the same position, to insure the fitting of each color upon the others. No mechanical means whatever are used, either in placing the sheet, or for holding it in position after it has been placed. The Japanese printer, in these matters as in all others, depends simply upon experience. The manner of placing the sheet on the block is shown on Plate XIII.

The same figure shows also the registering marks on the block or plank, which consist of a rectangular notch at the right, and a straight notch at the left.

General remarks about printing. The printing may differ in quality, but the method employed is always about the same. The printing of a picture like "Nandina domestica" [which is an imitation of a water color painting without outlines] requires, of course, greater skill than the printing of "Yinaka genji" [which is a drawing in outlines, with color washes]. The aim in this case is to produce impressions which an inexperienced eye can hardly distinguish from the original. But there is no special way of treating either class of prints. The difference between the best and the less good is due entirely to the skill of the printer in producing the various hues, tints, and shades with printing brushes, in precisely the same way as the water-color painter. This holds good also of the engraver. The arts of engraving and of printing are practiced in Japan according to the dictates of experience, with no, or at the most but very slight, mechanical assistance.

COST OF DESIGNS. The original design of "Yinaka genji," by Kuniteru, called also Yichiyusai, cost 10 yen (about $7.60).

That of "Nandina domestica," by Chinzan, Tsubaki, cost the same sum.

COST OF ENGRAVING. "Yinaka genji," engraved by Kokichiro, Morikawa, cost 16 yen (about $12.30), and took the engraver about 20 days. [The three sheets, executed respectively in 25, 26, and 23 printings, or in all 74 printings, required the cutting of 37 blocks. See the notes by the editor (in the next section) concerning the discrepancy between number of printings and number of blocks.]

"Nandina domestica," engraved by Kotaro, Kido, cost 8.4 yen (about $6.38), and took about seven days in the doing. [There are 33 printings, but the number of blocks used is not stated.]

COST OF PRINTING. The printer of "Yinaka genji," Tsurusaburo, Nakamura, received 70 sen (about 54 cents) per day. He printed 3,000 sheets per day from the black block, and 700 to 800 sheets per day from the color blocks.

The printer of "Nandina domestica," Yiwakichi, Yamamoto, received one yen (about 76 cents) per day. He finished about 200 sheets per week.

The people engaged in home industries do not generally take a rest on Sunday. The week, therefore, has seven days of about eight hours each. As "Nandina domestica" has 33 printings, 200 finished sheets are equal to 6,600 impressions per week, or 943 per day. The numbers differ, however, according to the different nature of the blocks. Of the easiest, for instance, such as a uniform green for the leaves, 1,200 to 1,800 sheets can be printed in a day, while of the most difficult ones, such as those giving the half-tints in the fruit, only 600 to 700 sheets can be printed.

(This is the end of Mr. Tokuno's communication. The next part of the volume is the Museum Editor's comments and Notes)