A Curved Gradation

Curved Gradations

Gradations are tough to keep consistent through an edition; making one is no problem, but making two hundred all pretty much the same is a different story! And when the gradation runs along a curve the job is much more difficult.

The job can be eased a lot through the use of a simple 'jig' to guide the brush. Here's a series of photographs showing the process of printing a curved gradation on one of my 'surimono' prints - a fan-shaped design ...

It's not so clear in this next photograph, but this circular object placed on my carving desk is a 'lazy susan'. It's a cork- topped circular disk of wood, mounted on a store-bought piece of turntable hardware. The whole thing has a wooden base with cork feet, and it sits firmly on my printing bench. This isn't absolutely necessary for making curved gradations, but it does make the brushing part easier ...

The carved woodblock sits on top of the disk, held by the cork. You can also see a white ceramic tile, on which sits a piece of folded and dampened rag (which has already been used for taking a number of impressions - thus the blue stains ...)

Just below the turntable in that photo is the jig I mentioned. It is just a piece of wood cut to a shape that matches the path over which the pigment brush should move over the block.

There is a small hole drilled in each of the two top corners of the woodblock:

... and corresponding pegs on the jig:

So it just drops gently into place ...

That's the preparation; now for the actual printing procedure.

The first step is to dampen the block in the area that the gradation is to appear, by wiping it with the cloth (being careful to move the cloth in exactly the same path each time, to avoid smearing pigment into areas that it is not wanted.)

After every few impressions, this cloth is refolded, to 'hide' the stained area, and it is also touched with the water brush to refresh the moisture.

With the block properly moistened - moving along quickly before it can dry out - the hakobi is used to apply some dabs of pigment here and there along the edge of the wood. The pigment is quite 'creamy', not thin and runny ...

Working quickly, drop the jig into the guide holes.

This is the touchy part ... holding the brush vertically, run it along the edge of the block back and forth until the pigment is distributed properly. It takes quite a 'touch' - too much pressure and the brush hairs splay out and the pigment scatters ... too light and the pigment is not smoothly brushed out.

My right hand is moving the turntable back and forth as my left hand runs the brush along the edge of the guide.

Because the pigment is quite thick, it is also necessary to occasionally dab the brush to the water brush to recharge it with moisture ... but not too much!

And of course, because only one side of the brush should carry pigment, it is necessary to be very careful not to turn the brush around between impressions ... mark one side so that you can keep it in the same orientation every time ...

Remove the jig, and put the paper in place in the kento marks.

Rub as normal with the baren ...

... and peel the paper from the block.

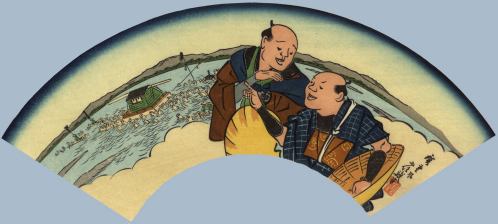

Here she is! (To get this nice deep blue gradation, I printed each sheet twice, and in some cases three times ...)

Photos by Sadako ...