Moistening Paper

Paper preparation ...

Before the actual printing can begin, the paper must be moistened. There are two main reasons for this: (1) if we tried printing on dry paper, it would expand unevenly as it absorbed the water from the blocks, and registration of multiple colours would then become impossible; and (2) the pigments will not 'sink in' properly if the paper is too dry and 'hard'.

One convenient way to moisten the paper is to

press it between sheets of wet newspaper for a couple of hours (many

printers do it the night before). Using a basin of water and a

mizubake (if you don't

have this specialist's brush, a wallpaper brush or wide, clean

paintbrush will do), brush water over alternate sheets of both the

printing paper and the sheets of newspaper, then wrap the stack in a

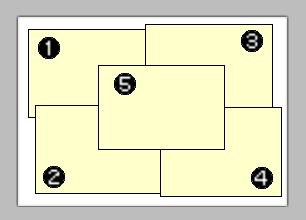

plastic bag and stack it between boards as shown in the picture until

the moisture has equalized.

One convenient way to moisten the paper is to

press it between sheets of wet newspaper for a couple of hours (many

printers do it the night before). Using a basin of water and a

mizubake (if you don't

have this specialist's brush, a wallpaper brush or wide, clean

paintbrush will do), brush water over alternate sheets of both the

printing paper and the sheets of newspaper, then wrap the stack in a

plastic bag and stack it between boards as shown in the picture until

the moisture has equalized.

What level of dampness are you aiming for? The printing paper should end up feeling about like a sheet that has just come out of the spin drier ready for hanging on the clothesline - damp and soft.

This simple method should suffice for many purposes, but if the paper dimensions are relatively large, or if the design contains small-scale elements that make registration critical, then a second step is necessary. The moistened paper needs to be allowed to expand freely as it absorbs the water, but while held tightly in that stack, it is unable to do so. So after it has been stacked in this fashion for a couple of hours, it must be re-stacked in a 'looser' form. There are a couple of common ways of doing this:

(1) The traditional methods use a wide board covered with moistened thick paper or smooth cardboard. On this moist surface, arrange the sheets of printing paper in 'staggered' fashion (the illustrations show two common methods: 'otosu' and 'hawasu').

When all the paper is in place, cover it with more of the moistened thick paper, and then cover the entire stack with moistened towels or heavy cloth.

The next morning, in preparation for printing, open the stack, quickly slide the paper into a single pile again, and place this in position ready for use, face down and covered with more of the moistened thick paper to keep it damp while it waits ...

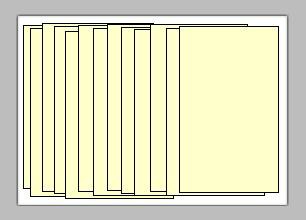

(2) Another method, and one that makes it somewhat easier for an inexperienced printer to control the moisture during the days of printing, is to use the same wide board covered with the moist thick paper, but on this lay some well-moistened newsprint (in 'eight-page' sections works well). On this place 5 sheets of your printing paper face up, slightly staggered, as in the second illustration above. Over this another newsprint section, and then 5 more sheets ... Continue until all the paper is in place. A few more sections of newsprint, and then cover it all with the moistened thick paper and towels as above.

At printing time, remove the towels and thick paper, and place the entire stack in position in front of the printing workspace (flipped over so the paper is face down). Flip some of the moist newspaper over to the side platform, then print five sheets. Flip the newspaper across, then print five sheets, etc. etc. Add moisture to the newsprint as necessary before re-covering for the night.